FULL EXAMINATION AND ANALYSIS

Comprehensive process for investigating the causes of distal stem breakage

SECTOR

Medical

PROBLEM

Breaking the prosthetic stem

MATERIAL

Grade 5 titanium

APPROACH

Macroscopic visual inspection

Stereomicroscope examination for accurate observation of fracture surfaces

Materialographic examination of fracture surfaces

SEM microscopy for fratographic examination

Material characterization with hardness measurement

RESULTS

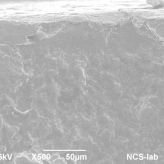

The prosthesis stem is made of grade 5 titanium alloy in compliance with ISO 5832-3 and ASTM F136, with a hardness of 318 HV10. The microstructure is homogeneously equassic, typical of the material in the annealed state, and does not present any anomaly.

The collected fracographic evidence, in particular the evidence of stable propagation with transgranular advancement, are in agreement in indicating a fatigue rupture by simple flexion, with trigger at the point of contact of the conical stele-neck coupling.

The extent of stable propagation indicates that the breaking loads are low. The bending stresses are compatible with the presumable system design of the component.

There are slight traces of surface wear in the area of the triggering zone, which typically favors the nucleation of fatigue fractures. This wear is likely to be caused by micro-fractures between the stem and neck and is a typical phenomenon on hip replacements of this type.