NCS supports STRETTO IN CARENA, the team of the University of Messina at the MOTOSTUDENT 2020

After the collaboration which brought SCIGHERA, the motorcycle designed by the PoliMi Motorcycle Factory, to win the MOTOSTUDENT championship, NCS | Newcast Services is ready to collaborate with another team of students. This team is from the University of Messina and it is called STRETTO IN CARENA, a young and determined team which will participate to the championship in the Petrol category with a petrol engine.

For the first time students will participate to the 6th edition of the MOTOSTUDENT international championship that will take place in Aragon in 2020.

MOTOSTUDENT is a four-day competition which calls to Aragon, Spain, students from universities from all over the world for a real race in which they have the chance to demonstrate their competences starting from the design of a project up to the creation of a prototype.

Marcello Fantuzzi, Techinical Director & President of NCS met the team at the Feltrinelli of Messina and has formalised the collaboration:

“I have the capability to lead you to Aragon. I am here to invest in your future because your future will be my profit and if you believe in what you are doing it will be so.”

The committment of NCS is to help students during the process of design and provide all the materials and means of production they need.

Fantuzzi also encouraged and provided valuable advice on the topic:

“The challenge is to sacrifice yourself and strive for an objective. Your team is very good one but the motorcycle is only one and it must be the best.”

and more

“You don’t have the requirements to go to Aragon, but you accepted the challenge anyway. This is what I saw in you. We will not go there to win but we will go there to join and win for ourselves.”

NCS is ready to collaborate and support the ideas of STRETTO IN CARENA, a team formed by 70 students at their very first experience but with a huge will of put themselves to the test with the big ones.

Motostudent >>> http://www.motostudent.com/

Stretto In Carena >>> https://strettoincarena.it/

NCS Lab challenges cold ice and winds of Alaska

Alaska 2019 Ski Walking Winter Expedition is the next expedition of the project Alaska Adventures which will cross Alaska and Canada during the frightful polar winter. Following the roads of Klondike gold rush, the expedition will be partly on skis which will tow a sled on the snow and partly on foot with the sled towed on wheels.

Why a sled?

The choice fell upon a sled both to transport materials and basic supplies but also to emulate the limited possibilities available to pioneers at the end of the nineteenth century and their lonely crossing in 1997.

NCS is sponsor of this project as provider of the hull and also of the two sleds laminated in carbon fiber designed by students of the Department of Material Science and Industrial Engineering of the University of Trento.

Tomorrow, December 6th 2018 Marcello Fantuzzi – Technical Director & President and Andrea Vecchi – Laboratory Manager will take part at the official presentation of the project:

The challenge will be 1300 km long for approximately 50 days facing cold, thin ice, temperature variations and....grizzly bears!

Find out more about the expedition here:

https://alaskaadventures.it/spedizioni/alaska-2019-ski-walking-winter-expedition/

NCSTeam wishes Maurizio Belli and Fulvio Giovannini good luck for the adventure!

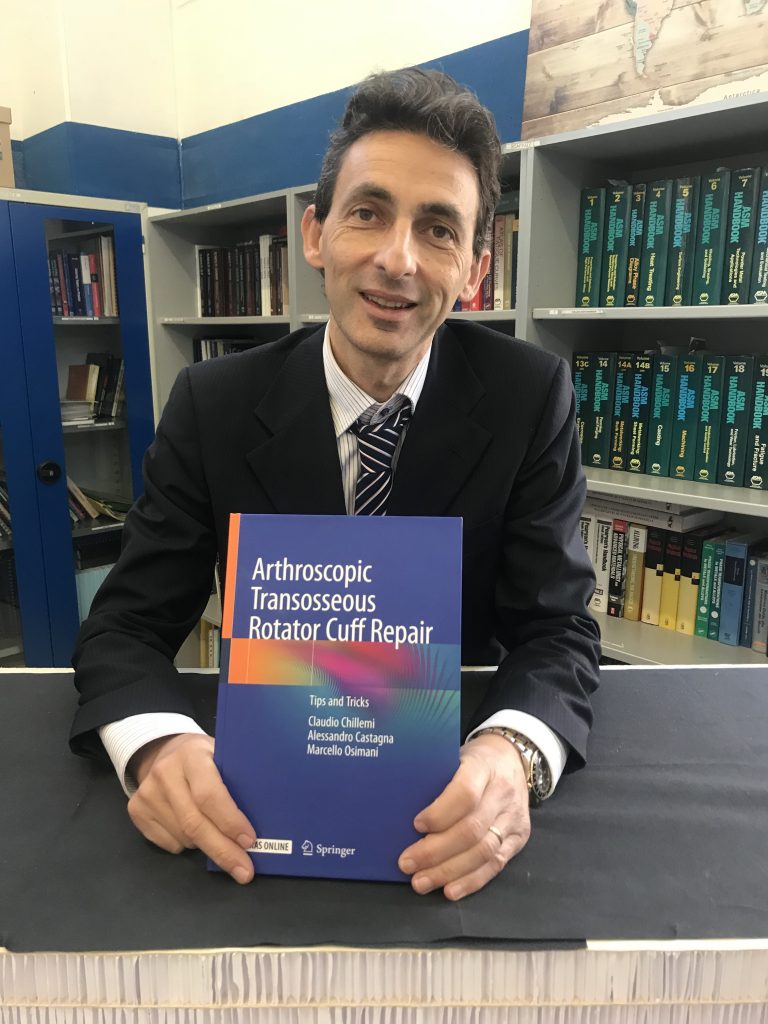

NCS presents “Arthroscopic Transosseous Rotator Cuff Repair”, the first monograph about transosseous

Tomorrow “Arthroscopic Transosseous Rotator Cuff Repair Tips and tricks” will be presented at the ICOT Institute (Surgery, Orthopaedy, Traumatology Institute) in Latina. Matteo Mantovani, CEO of NCS will talk about the arthroscopic surgical technique with the NCS Lab | Medical Devices Taylor Stitcher and about how this procedure improves the process of reconstruction of the rotator cuff. The procedure with Taylor Stitcher also guarantees several benefits for patients but also minimizes costs for operating rooms:

“This book covers all aspect of the transosseous approach, starting from foundation of biological science and progressing through postoperative rehabilitation. Along the way, the chapters discuss biomechanical factors and technologies in the marketplace, tracing the evolution over time, proposing solution and offering a view on the future. All of the material is supported by an impressive reference collection, which provides infinite possibilities to deepen one’s knowledge on the subject”

At the presentation, along with Matteo Mantovani, there will also be other authors:

- Claudio Chillemi – Author – Orthopaedic Aid at ICOT

- Alessandro Castagna – Author – Director of the Shoulder Operational Unit at the Humanitas Institute, Milan

- Marcello Osimani – Author – Radiology Operational Unit Polo Pontino

After the presentation, the audience will have the chance to attend a live surgery held by Claudio Chillemi and Alex Castagna.

Read an excerpt of the book here:

LOOK INSIDE: https://www.amazon.com/Arthroscopic-Transosseous-Rotator-Cuff-Repair/dp/3319761528/ref=mt_hardcover?_encoding=UTF8&me=&qid=1535559342

Further information about event here:

NCS | Taylor Stitcher:

https://ncs-company.com/case-history/medical-devices/sport-medicine/taylor-stitcher/

NCS goes to Boston for the event “Transosseous Academy 2018”

“Transosseous Academy”, the first international convention and the second annual event, has just finished in Boston. NCS was main sponsor.

“Transosseous Academy”, the first international convention and the second annual event, has just finished in Boston. NCS was main sponsor. “Transosseous Academy” is an independent and non-profit association born in order to promote and support scientific research, innovation and foster knowledge sharing on the transosseous surgical technique.

The mission of the association is to put together clinicians, engineers and scientists to create an interactive environment in which propose and carry out research leading to more and more positive results for patients.

Transosseous Academy combines the engineering sphere with the clinical and medical sphere in a brand-new field oriented towards science and the sharing of results. TA’s primary objective is to collect clinical data in order to highlight and support the surgical treatments studied.

NCS | Medical Devices supports the project “Transosseous Academy” realised in Milan during the first meeting in 2017 and in the first international event held in Boston last 10th of November. NCS has always been active in the processes of design and production of implantable biomedical devices intended and dedicated to arthroscopic techniques which became even more effective. For this reason, NCS sustains the mission of Transosseous Academy.

An international faculty held speeches, lectio magistralis and re-live. The various interventions covered all the aspects of transosseous from biomechanics to biology, from the several techniques available today to a new way of collecting in an objective way clinical data leading to clinical results. An exceptional faculty able to elevate scientific content and maintain an interactive and stimulating environment.

NCS and Transosseous Academy would like to thank Dr Alessandro Castagna, chairman and former supporter of TA all the members of the faculty (mentioned below). A sincere thanks to Dr Snyder who shared his unbelievable experience and carrier full of success and innovation.

Faculty:

Stephen Snyder, MD – USA

August Mazzocca, MD – USA

Claudio Chillemi, MD-ITA

Cory Edgar, MD – USA

Myriam Capasso, MD – VE

Andrea Pellegrini, MD – ITA

Jean Kany, MD – FRA

Sumant Krishnan, MD – USA

Uma Srikumaran, MD – USA

Matteo Mantovani, Eng.-ITA

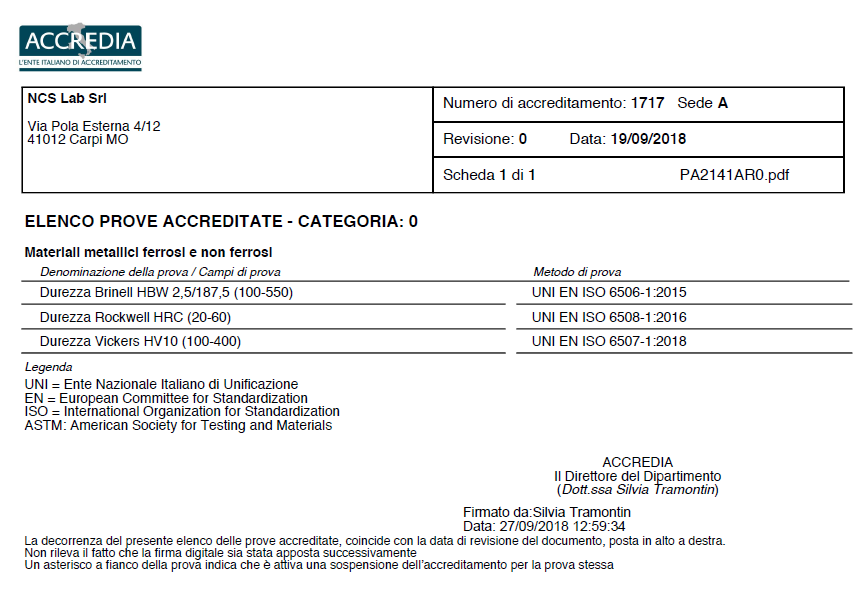

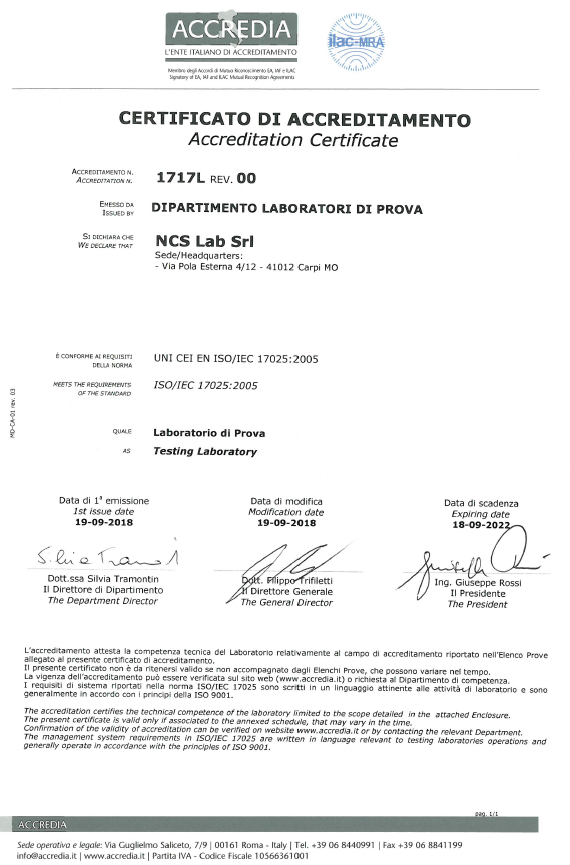

UNI CEI EN ISO/IEC 17025:2005 Certification

NCS Lab srl has obtained ACCREDIA accreditation according to the UNI CEI EN ISO/IEC 17025:2005 standard.

We are pleased to announce the certification of the Accredited Laboratory LAB No. 1717L of September 19, 2018: "General requirements for the competence of testing and calibration laboratories" for the following tests:

- Hardness Brinell HBW 2,5/187,5 (100-550)

- Hardness Rockwell HRC (20-60)

- Hardness Vickers HV10 (100-400)

Being in compliance with the requirements of ISO/IEC 17025:2005 means to possess both the technical competence required to carry out the analyses and a quality management system, which is essential to guarantee the correctness of the analytical data and the traceability of the measurements.

As accredited laboratory, NCS is able to provide reliable, credible and nationally and internationally accepted declarations of conformity and guarantees:

- Impartiality

- Independence

- Correctness

- Competence

The UNI CEI EN ISO/IEC 17025:2005 standard is international and is accepted in all countries of the world.

The list of tests approved is available at www.accredia.it

ACCREDIA assesses the technical competence and professional suitability of the operators of the Testing Laboratories, verifying their compliance with mandatory rules and voluntary standards, to ensure the value and credibility of certifications, inspections, tests and calibrations.

Accreditation ensures that test and inspection reports and certifications (system, product and personnel) bearing the ACCREDIA mark are issued in compliance with the most stringent international requirements for conformity assessment, and behind constant and rigorous surveillance of the behaviour of testing laboratories.

Test list

Certificate

Certificate

SCIGHERA wins MOTOSTUDENT 2018, the world championship

SCIGHERA, the motorcycle designed by Polimi Motorcycle Factory won MOTOSTUDENT, the worldwide championship held in Aragon where teams of university students from all over the world competed in several challenges.

NCS | Newcast Services followed the team step by step during the process of design from the project to the prototype of the motorcycle.

WHAT IS MOTOSTUDENT?

MOTOSTUDENT (5th edition in 2018) is an international competition for motorcycles designed by teams of university students from all over the world who build the motorcycle from scratch.

The race is becoming more relevant year after year both at a university level but also for the motorcycling sector too. More than 1500 students from more than 50 different universities in the world are involved.

The mission of every single team is to design, create and evaluate the motorcycle prototype that will be put to the test at the Aragon racing circuit.

Teams have to pretend to be the manufacturer and try to sell their product to costumers developing the industrial project of a motorcycle starting from a prototype.

COMPETITION STAGES

The competition is divided into two stages: MS1 and MS2.

• MS1: design, innovation and industrialization.

At this stage teams present their industrial project related to the hypothetical mass production of the prototype. Following rewards are assigned at this stage:

- best design award

- best technical innovation

• MS2: dynamic tests.

The second stage comprises several dynamic tests to evaluate some aspects like acceleration, braking and manoeuvrability.

This stage concludes with a speed race made of 8 laps.

POLIMI TEAM AND NCS

Polimi Motorcycle Factory is the team of the department of Mechanic Engineering of the Politecnico of Milan, born in 2015 from the ambition of 5 future engineers.

The experience of NCS in Moto2 Championships and also in other international championships together with the employment of innovative technologies and also the passion for the automotive sector, prompted the relation between NCS and Polimi. For these reasons NCS is main sponsor of the project and realized the official prototype.

NCS followed the team in this two-years journey, realising hulls, airbox, structural coatings, frame and swingarm made of steel and composite materials.

The technology used for the realization of the aerodynamic and structural part is called XtremeHS+.

NCS | Newcast Services’ experience, competences and also 3D printing technologies were available for the team of engineers of the PoliMi. SCIGHERA is the final result, a great value result.

SCIGHERA is the name of the motorcycle prototype designed by the PoliMi Motorcycle Factory. Scighera in Milanese dialect means “fog”, an omnipresent element during the period of work of the team!

RESULTS

This project, lasted two years, with tests and obstacles along the way, has payed off during the first weekend of October in Aragon, Spain.

This project, lasted two years, with tests and obstacles along the way, has payed off during the first weekend of October in Aragon, Spain.

PoliMi Motorcycle Factory finished 2nd at the MS1 stage and also achieved the top of the podium in dynamic tests, acceleration tests and highest speed.

The team also gained extra points thanks to the 2nd position in the mechanic test, the 2nd position in qualifications and 2nd fastest lap.

Winning the final race brought the Milanese team directly to the world champion title of Motostudent 2018.

Below the numbers of this success:

- 1st MS2 petrol – Dynamic tests

- 1st Place in Race

- Best Acceleration 6”966

- Best Top Speed 197,1 km/h

- 2nd Best Mechanical test 0’28”400

- 2nd MS1 – Design of the motorcycle, Innovation and Business analysis

- 1st Motostudent petrol ( MS1+MS2 )

NCS AS SPONSOR OF A WINNING PROJECT

Since its earliest days NCS | Newcast Services was main sponsor of PoliMi Motorcycle Factory and it is moving for us having reached with you these results, as Marcello Fantuzzi, Technical Director & President of NCS | Newcast says:

“After the unfortunate debut of NCS & PoliMi at the 2016 MotoStudent, the team decided to employ all the enthusiasm, love and passion in this project with the sole aim of building a plain on wheels for the 2018 MotoStudent. And that was the result obtained... welcome to the #PolimiAirlines, congratulation to all guys!!!

The world is yours!!!”

POLIMI MOTORCYCLE FACTORY >>> http://www.polimimotorcyclefactory.it/

MOTOSTUDENT >>> http://www.motostudent.com/

Let’s design the intelligent factory together

Let’s design the intelligent factory together: a path dedicated to practical applications of enabling technologies for production

NCS will take part to the meetings promoted by the Research and Innovation Area of Confindustria Emilia. These meetings are organized in order to foster a fruitful contamination of “good practices” linked to enabling technologies for the development of the “intelligent factory”.

The participation of NCS will be during the workshop:

“Collaborative robots: product efficiency applications”

September 19th 2018, 16:00 - C/o Confindustria Modena

The meeting is aimed at presenting potentials and usages of “collaborative robots” able to share the working space and work closely with operators without causing danger for them.

Collaborative robotics lies between automated assembly and manual assembly typical of small production batches but with a high number of variants.

The focus is the relation between man and machine and the detailed ergonomic evaluation of tasks in order to guarantee safety, sustainability and optimization.

INFORMATION and REGISTRATION >>>>

Cogito Ergonomics

We will talk about COGITO ERGONOMICS, the innovative platform for the movement analysis applied to the ergonomic world.

We will talk about COGITO ERGONOMICS, the innovative platform for the movement analysis applied to the ergonomic world.

Our technology uses wearable sensors for the optimization of products and processes of production for the work planning. These wearable sensors will be adjusted to the workers’ needs in order to better manage:

- PRODUCT ERGONOMICS

- PRODUCTION LINE ERGONOMICS

- OFFICE ERGONOMICS